The Best Scroll Saw

We looked at the top 7 Scroll Saws and dug through the reviews from 11 of the most popular review sites including and more. The result is a ranking of the best Scroll Saws.

Our Review Process

Don't Waste Your Money is focused on helping you make the best purchasing decision. Our team of experts spends hundreds of hours analyzing, testing, and researching products so you don't have to. Learn more.

Our Picks For The Top Scroll Saws

- 1. DEWALT DW788 20-Inch Variable-Speed Scroll Saw, 1.3 Amp

- 2. WEN 3921 16-Inch Two-Direction Variable Speed Scroll Saw

- 3. General International 1.2 Amp 16-Inch Variable Speed Scroll Saw

- 4. RYOBI 1.2 Amp Corded 16-Inch Scroll Saw

- 5. Jet 22-Inch Scroll Saw With Stand

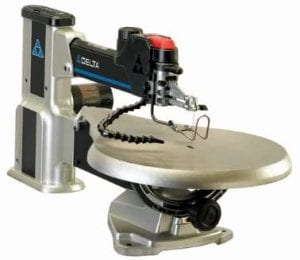

- 6. Delta Power Tools 40-694 20-Inch Variable Speed Scroll Saw

- 7. SKIL 3335-07 16-Inch Scroll Saw With Light

This scroll saw is defined by its arm, which can be moved up to allow the blade to be placed inside the work piece for cutting hard-to-reach places. The double parallel-link arm design reduces noise and vibration, while the oversized cast iron table can bevel both left and right.

Liftable Arm for ThreadingFor accurate cuts, convenient features and smart design, this saw is a solid choice.

The unique design of this scroll saw allows for the use of blades in both standard and 90-degree directions for greater ripping capacity. The 16-inch throat, adjustable work light and variable speed (400 to 1600 strokes per minute) give you the flexibility you need for detailed projects.

Two-Direction Blade UseThis unique scroll saw is an excellent choice for projects with a larger maximum width.

This low-noise, minimal shaking, variable-speed scroll saw incorporates convenient features such as a flex-neck work light, dust port and dust blower to make sure you can see your cut line with ease. The patented blade holder design accepts both pinned and pinless saw blades, while the top-mounted tension knob allows for easy adjustment of the cutt...

Variable Speed, Low VibrationThis scroll saw presents a dependable, convenient option that keeps the focus on getting the job done.

Buying Guide

Scroll saws are a type of power tool consisting of a table, arm and a vertically-oriented thin blade intended to work on detailed or intricate pieces. Scroll saws and scroll saw blades are designed for precision rather than power, so they tend to be lower-amperage than other saws. The blade moves up and down through a hole in the table, and it can be threaded through a workpiece to make interior cuts.

Key considerations when purchasing a scroll saw include arm type, throat size, table material and bevel and blade type. The arm of the scroll saw arches over the table and holds the saw blade, and there are three types of arm configurations.

C-type arms contain one pivot point, allowing the blade to mode in an up and down position. However, because there is one pivot point, the blade moves in a slight arc. These arms provide a faster cut, but they can cause a lot of vibration and noise, and generally require more skill to operate.

Parallel type arms contain two arms which meet each other in the middle and contain a pivot point in each arm, allowing the arms to travel simultaneously and allowing the blade to move in a reciprocating motion, upwards and forwards.

Finally, parallel-linked arms, the newest style of scroll saw, greatly reduce noise and vibration, allowing for greater accuracy and precision. The arms on these saws are much shorter than on a C or parallel arm, and they pivot, allowing the blade to reciprocate the motion.

After arm type, throat size is often the next-biggest consideration. The throat is the distance between the blade and the back of the tool where the arms meet, and this determines the size of the work piece that can be maneuvered around the blade.

The most common throat sizes range from 16 inches to 20 inches. A sturdy table material is also a must. Tables are commonly made from aluminum, steel or cast iron. Finally, many scroll saws include amenities such as work lights, dust blowers and dust ports to keep the cut line clearly visible. Blades also impact the type of work that can be done, but they are sold separately, and most scroll saws accept every type of blade.

Why we recommend these scroll saws?

Products Considered

Products Analyzed

Expert Reviews Included

User Opinions Analyzed

Our experts reviewed the top 7 Scroll Saws and also dug through the reviews from 11 of the most popular review sites including and more. The result is a ranking of the best of the best Scroll Saws.

DWYM is your trusted roduct review source. Our team reviews thousands of product reviews from the trusted top experts and combines them into one easy-to-understand score. Learn more.

What to Look For

- Carefully assess your skill level before purchasing a scroll saw. While some scroll saws give a faster cut, they often require more skill to operate. A slower but steadier scroll saw can be a better choice for a beginner.

- It’s also essential to order work gloves, safety goggles and a dust mask when you purchase your scroll saw. In addition to long-sleeve shirts, long pants and steel-toed shoes, these pieces of safety gear are essential for work with power tools.

- Check the bevel capabilities of the table. While many scroll saw tables cannot bevel (tilt to allow angled cuts), many can do so for up to 45 degrees to the left, right or both. Not all projects or craftspeople require this capability, but it can be the deciding factor between two otherwise comparable scroll saws.

- The type of blade in the scroll saw greatly impacts the work that can be done and the skill level required to do it. Some types of blades, like reverse-tooth blades, are particularly suitable to materials like plywood that can chip when cut.

More to Explore

The origins of the scroll saw are not entirely clear, but a patent for one from 1829 has been discovered. As fretwork — the sawing of intricate shapes from wood — became more popular, the scroll saw evolved.

While fretwork dates back to ancient Egyptian, Greek and Roman times, this woodwork was carved by hand. Mechanical means of creating fretwork did not come about until the 1860s in America. The great variety of blades, with eight popular blade types currently in use, grew out of the popularization of this craft and hobby.